California

Businesses Partner with STEM Students

Where mechanical and electrical engineering, computing technology, automated control and information systems intersect are graduates from the mechatronics engineering technology program based at PennWest California.

Where mechanical and electrical engineering, computing technology, automated control and information systems intersect are graduates from the mechatronics engineering technology program based at PennWest California.

“Making robots is a really common application for mechatronics,” said Dr. Jennifer Wilburn, chair of the Department of Applied Engineering, Technology and Physics. “Because we are located in southwestern Pennsylvania, we focus on advanced manufacturing, because we have a lot of manufacturing jobs. Our students want jobs when they’re done.”

Wilburn helped to build the mechatronics engineering technology program, which launched in 2013 as the first hands-on, technology-focused, four-year program of its kind in Pennsylvania’s State System of Higher Education.

One highlight is the Industrial Advisory Board, a key component to ensuring the program is accredited by the Engineering Technology Accreditation Commission of the Accreditation Board for Engineering and Technology.

Member businesses provide input into the program in order to ensure graduates are workforce ready. Some sponsor the students’ senior projects.

“Businesses come to us with problems in their production process that maybe aren’t big enough for a contractor to pick up,” Wilburn says. “Maybe it’s not urgent, but it’s something they would like to address.”

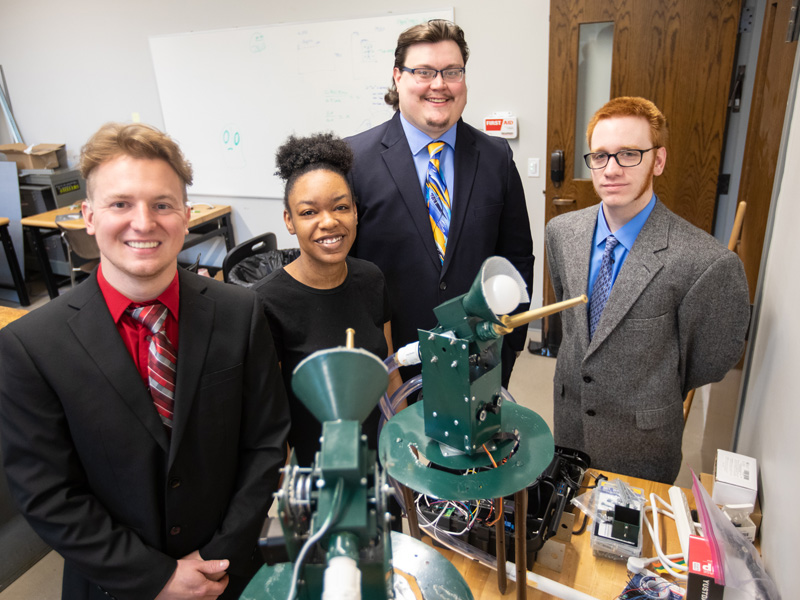

The business provides the parts and a mentor. Students flesh out the complexities and design a solution. Final designs are presented to the Industrial Advisory Board before students graduate.

Julietta Maffeo ’22 and her team presented their project in partnership with DMI Companies, a leader in HVAC products and services. They wheeled their label applicator for ceiling radiation dampers from the classroom to a truck for delivery to the company’s production floor. The project eliminates drying time and labor on more than a million parts produced each year.

“What DMI seemed to like about me is that I knew the manufacturing side and engineering side as well,” said Maffeo, who also studied electrical engineering technology and now works for DMI as an automation engineer. “I had hands-on experience with programmable logic controllers and automation equipment – stepper motors, robotics and circuit design.”

Maffeo returned to California last fall as an industry partner and guest presenter on AutoCAD Electrical, a product that is important in understanding electrical drawings.

“It works out well for the students,” Wilburn said. “They get feedback from the industry and the durable skills they will need in the workforce.”